[HOME ] [ABOUT] [PHOTOS] [VIDEO] [BLOG] [HOUSTON] [TEXAS] [U.S. NEWS] [WORLD NEWS] [SPORTS] [POP CULTURE] [CONTACT]

Syria chemical weapons to be destroyed by US Army on ship

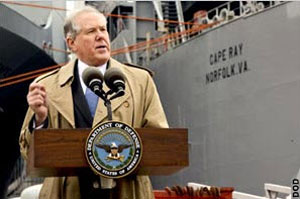

Under Secretary of Defense Frank Kendall speaks

to reporters during a visit to the American-owned ship

Cape Ray in Portsmouth, Virginia, on January 2 to

discuss the ship's upcoming mission to destroy chemical

weapons from Syria. —Photo: Department of Defense

by Joseph Earnest January 7, 2014

Newscast Media PORTSMOUTH, Virginia—Some 64 U.S. Army specialists are expected to depart for the Mediterranean in about two weeks aboard an American-owned ship, the Cape Ray, to destroy chemical weapons from Syria.

The nearly 200-meter-long ship, now in Portsmouth, will travel to a yet-to-be specified location in the Mediterranean, where it will take on about 700 metric tons of both mustard gas and "DF compound," a component of the chemical weapon sarin gas. Specialists will use two new, recently installed "field-deployable hydrolysis systems" to neutralize the chemicals.

It’s expected the weapons destruction will take about 90 days.

During a visit to the Cape Ray on January 2, Frank Kendall, undersecretary of defense for acquisition, technology and logistics, said preparations began before the United States even knew it was committed to the mission, or that the mission would ever materialize.

"There was a recognition that something was going to happen in Syria … that would require us to do something with those chemical materials that were known to be there," he said.

In December 2012, a request was made to determine what could be done if the U.S. was asked to participate in destruction of chemical weapons from Syria.

By the end of January 2013, a team had evaluated existing technology for neutralization of chemical weapons and recommended using the hydrolysis process. Construction of a deployable system began in February, and the first prototype was available in June. A second was available in September.

“We could have waited to see what happened and then reacted to that, or we could have moved out ahead of time and then prepared for what might happen or was likely to happen,” Kendall said. "Fortunately … we took the latter course."

Aboard the ship, an environmentally sealed tent contains two FDHS units, which will operate 24 hours a day in parallel.

Each unit costs about $5 million and contains built-in redundancy and a titanium-lined reactor for mixing the chemical-warfare agents with the chemicals that will neutralize them.

About 130 gallons of mustard gas can be neutralized at a time, over the course of about two hours, for instance, said Adam Baker of the Edgewood Chemical Biological Center in Edgewood, Maryland.

The plan is not to start out on the first day at full speed, Baker said. "It's going to be a slow start. We’re going to go very deliberately and safely."

The neutralization process will create about 1.5 million gallons of a toxic "effluent" that must be disposed of. Rob Malone of Edgewood said the effluent is similar to other toxic compounds that industrial processes generate. There is a commercial market worldwide for disposing of such waste, he noted.

Baker said the effluent will be acidic and will be PH-adjusted to bring it up to "above neutral." The end result will be a liquid that is caustic, similar to commercial drain openers, he said.

Malone said the plan includes a cycle of six days of disposal plus one day for maintenance of the equipment. On board will be about 220 6,600-gallon containers that will hold the reagents used in the disposal process, and will also be used afterward to hold the effluent.

"Everything will be kind of contained on the ship throughout the entire process," Malone said.

The United States has never disposed of chemical weapons on board a ship before. But it has spent years disposing of its own chemical weapons on land, using the same process that the FDHS uses. The chemical process is not new, and neither is the technology. The platform, aboard a ship, is new. This has created challenges for the team.

“This has not been done on this platform, not been done at sea,” Baker said. "But it is taking the established operations we've done at several land sites domestically and internationally and is applying them here."

In the United States, the U.S. military has been destroying its own chemical weapons for years at Aberdeen Proving Ground, Maryland, and the recently closed Pine Bluff Arsenal, Alabama. Lessons from those facilities and others were used to develop the process that will be used aboard the Cape Ray.

The process for disposing of mustard gas was used at Aberdeen Proving Ground. The process for disposing of DF compound was taken from Pine Bluff Arsenal, Baker said.

"So there is no mystery about the process," Kendall said.

Malone, who has 20 years of experience destroying chemical weapons for the United States, said doing on a ship what he has done on land for two decades required some additional thought and effort. Vibration studies were done to learn how lab equipment would operate on board a ship. The equipment had to be modified to anchor it to the ship using chains.

Rick Jordan, captain of the Cape Ray, a mariner for 40 years and an employee of contractor Keystone Shipping Company, said for this mission his crew expanded from 29 to 35. The additional six will support mainly what he calls "hotel services" on board the ship.

"We've got some really good folks on here that know how to train, and we've been training them," he said. "They've got all kinds of shipboard damage control, damage-control training and that sort of thing."

He also said there is plenty of support for spill response as well as for fire suppression.

"The whole key here is teamwork," he said. "There has been an unbelievable amount of teamwork in this whole process, from the Maritime Administration, Military Sealift Command, to the Keystone Shipping Company. I'm humbled by what is going on here. We’ve had about three or four days of hard training together where we’ve been making mariners out of them, and they’ve been making chemical destruction folks out of us. And we’re going to continue to train. The whole trip will be a combination of production, training and being ready for the worst-case scenario."

Jordan said he has not yet received sailing orders, but estimated the time to sail to the center of the Mediterranean Sea at about 10 days.

"Weather is the single most important factor as a mariner that I have got to consider," Jordan said. "The good news for the Cape Ray is we have lots of things to mitigate weather on board."

He said the ship is equipped with stabilizers to dampen any roll. He also said that because the ship is meant to serve as a platform without a destination, he can navigate around weather if needed.

Sea trials for the mission have already begun, and the Cape Ray will do more sea trials before it departs on its mission in about two weeks. It’s expected the mission will include the neutralization of about 700 metric tons of chemical weapon agents. Those agents will be transferred to the Cape Ray from Danish and Norwegian ships in a process expected to take one or two days.

"Exactly where and how that process will take place has not been finalized yet," Kendall said.

U.S. Navy assets will provide security for the ship while it conducts operations, Kendall said. Add Comments>>

Source: Department of Defense

|

|

Join the Newscast Media social networks

for current events and multimedia content.

Copyright© Newscast Media. All Rights Reserved. Terms and Privacy Policy